rfid card core factory Wherever you are on the supply chain, Radio Frequency Identification can provide benefits and its popularity has increased because of its variety of uses. Ideally, by this point, you have . See more For NFC payments to work, someone has to hold their mobile device or tap-to-pay card close to an NFC-enabled reader. The reader then uses NFC technology to search for and identify that payment device. Once it finds .Generate a private public key pair. Set a password to protect the key pair. Write the public key to share NFC and keep the private key in a safe place. Whenever a user wants to access the public key to decode a message , it will be prompted for a password to use the .

0 · where to buy rfid tags

1 · where to buy rfid chip

2 · rfid tag embedded label manufacturers

3 · rfid shop

4 · rfid readers and tags

5 · rfid label manufacturers

6 · corerfid log in

7 · corerfid limited

No, Square Reader for magstripe only accepts swiped (magstripe card) .

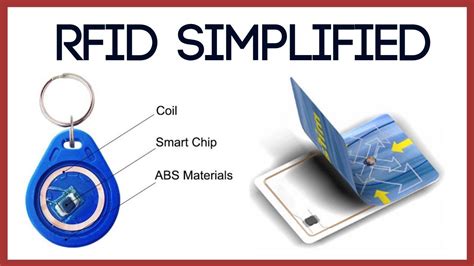

Radio Frequency Identification (RFID) has seen a host of uses from security systems to replacing tickets at theme parks. RFID technology is popular across the globe and has seen everyone from local businesses to multi-national companies explore its implementation. When we are referring to RFID in manufacturing . See moreA lot of people compare RFID and NFCtechnologies as both rely on short range communication between two devices to share . See moreAs there is a myriad of uses for RFID in Manufacturing, we are going to cover some of the core areas within the technology that is . See moreWherever you are on the supply chain, Radio Frequency Identification can provide benefits and its popularity has increased because of its variety of uses. Ideally, by this point, you have . See more

In this section, we will briefly look over some of the benefits of RFID in Manufacturing. We will aim to cover broad benefits which should benefit the majority of manufacturers and try not to be too niche. See moreFounded in 2010, over the years, CardCube has become the market leader for smart cards, RFID wristbands, keyfobs, and RFID custom products. As the largest manufacturer of RFID custom . Having the ability to access real time product execution information allows a factory to speed up its processes and limit downtime. RFID Tags allow you to determine, manage, and modify production steps to each unique project.Founded in 2010, over the years, CardCube has become the market leader for smart cards, RFID wristbands, keyfobs, and RFID custom products. As the largest manufacturer of RFID custom products, CardCube owns three marketing teams, one .

Because the manufacturing industry uses RFID in multiple ways, we will introduce some of the core areas where the technology is implemented throughout the process. This will help you understand how important RFID technology has become in modern manufacturing business.Explore how RFID solutions optimize the garment industry, enhancing efficiency from factory production to end consumer experience.RFID tags can track and monitor the whole process of raw materials and parts from arrival to production in real time. By embedding RFID tags in materials, manufacturers can understand inventory levels, reduce shortages, and optimize replenishment processes.RFID is a cost-effective way to track components or materials through the production process and ensure they are in the right place at the right time. It can also be used to track bulk containers, moulds or tools and ensure they are maintained properly.

RFID manufacturing solutions can electronically identify sub assemblies or trolleys, pallets or stillages using UHF RFID tags. The system can know that items have passed through all the steps needed to complete them.RFID access control systems can restrict access to only trained personnel and engineers and safeguard against industrial espionage. They also provide transparency over who is using the machinery and when in order to optimise processes.

Radio Frequency Identification (RFID) cards have become an integral part of various industries, including logistics, retail, healthcare, and more. As a professional RFID card manufacturer, CoreRFID understands the importance of maintaining high-quality standards throughout the manufacturing process.Since 2004, Cardy has owned the complete manufacturing sectors of RFID labels,tags and cards: inlay manufacturing, complexing, printing and encoding of the tags/labels,cards and wristbands. Big batch production capacity and flexible MOQ, accepting personalized customization. Having the ability to access real time product execution information allows a factory to speed up its processes and limit downtime. RFID Tags allow you to determine, manage, and modify production steps to each unique project.Founded in 2010, over the years, CardCube has become the market leader for smart cards, RFID wristbands, keyfobs, and RFID custom products. As the largest manufacturer of RFID custom products, CardCube owns three marketing teams, one .

Because the manufacturing industry uses RFID in multiple ways, we will introduce some of the core areas where the technology is implemented throughout the process. This will help you understand how important RFID technology has become in modern manufacturing business.Explore how RFID solutions optimize the garment industry, enhancing efficiency from factory production to end consumer experience.RFID tags can track and monitor the whole process of raw materials and parts from arrival to production in real time. By embedding RFID tags in materials, manufacturers can understand inventory levels, reduce shortages, and optimize replenishment processes.

RFID is a cost-effective way to track components or materials through the production process and ensure they are in the right place at the right time. It can also be used to track bulk containers, moulds or tools and ensure they are maintained properly.RFID manufacturing solutions can electronically identify sub assemblies or trolleys, pallets or stillages using UHF RFID tags. The system can know that items have passed through all the steps needed to complete them.RFID access control systems can restrict access to only trained personnel and engineers and safeguard against industrial espionage. They also provide transparency over who is using the machinery and when in order to optimise processes.

Radio Frequency Identification (RFID) cards have become an integral part of various industries, including logistics, retail, healthcare, and more. As a professional RFID card manufacturer, CoreRFID understands the importance of maintaining high-quality standards throughout the manufacturing process.

how do i apply for a smart id card online

where to buy rfid tags

where to buy rfid chip

rfid tag embedded label manufacturers

Now when you select the NFC function on the Flipper you can select which .nfc file you want- click Emulate- and tap it to your Switch's joystick to use! Credits:I used Link's Backup Amiibo Archive for the .bin'sAnd FlipMiibo (and its .

rfid card core factory|rfid label manufacturers