rfid system for injection molds The manufacturing RFID system embeds RFID tags into injection molds, allowing each mold to carry unique identification information. RFID readers collect this data and interface with software that manages mold location, status, and usage history. $7.95

0 · rfid injection molding

1 · injection molding solutions examples

2 · injection molding solutions

3 · injection molding plastic parts

Fremont Bank offers many different levels of built-in security and safety features on our debit cards: Chip Technology Fremont Bank debit cards are secured with a built-in microchip. .

Did you know that Radio Frequency Identification (RFID) can be a powerful tool for protecting and tracking valuable injection molded parts and components? RFID systems use radio waves to transfer data, making them highly effective in a variety of environments. Durable RFID Tags for .The manufacturing RFID system embeds RFID tags into injection molds, allowing each mold to .Würth Elektronik, a German company that manufactures printed circuit boards, has developed .

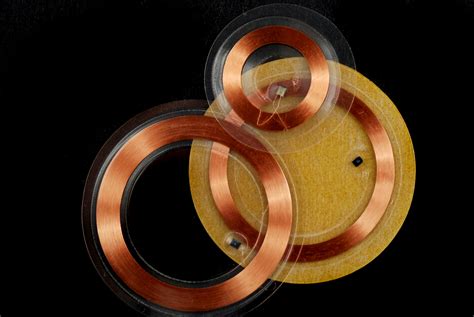

Did you know that Radio Frequency Identification (RFID) can be a powerful tool for protecting and tracking valuable injection molded parts and components? RFID systems use radio waves to transfer data, making them highly effective in a variety of environments. Durable RFID Tags for Harsh Conditions.The manufacturing RFID system embeds RFID tags into injection molds, allowing each mold to carry unique identification information. RFID readers collect this data and interface with software that manages mold location, status, and usage history.Würth Elektronik, a German company that manufactures printed circuit boards, has developed a tag that can withstand the injection-molding process, so it can be embedded in crates (see Würth Elektronik Manufactures a Tougher Breed of Tag).This white paper aims at using the example of manufacturing plastics with injection molding machines to describe how Industry 4.0 can quite easily gain entry into production, make processes more efficient and minimize costs.

Embeddable RFID Tags for Manufacturing are designed to be injection-molded by OEMs and suppliers into their consumables, parts, and systems. By adding RFID capabilities at point-of-manufacture , they enable the digitization of integrated supply chains with real-time information and added flexibility.

rfid injection molding

Identify, protect and track valuable assets with embedded RFID. Texas Injection Molding collaborates with leading RFID hardware and Systems Integrators to bring the experience of plastic injection molding to embedded RFID. Balluff offers a simple plug-and-play solution to record and manage injection mold data. Using RFID, our new digital tool management system, Connected Mold-ID, provides tool data including details of the tool’s history, production cycles, and current status of the individual Mold-ID systems.Connected Mold-ID is the simple entry into digital tool management. With this plug-and-play solution you can collect and manage your injection molds automatically. Connected Mold-ID enables optimal utilization of your molds while preventing mold failures and reducing unplanned downtimes. The autonomous RFID system reliablyThe automatic documentation of mold usage via RFID enables optimal utilization and high availability of your injection molds. A separate shot counter records all production cycles for this purpose and the system provides you with all data on a .

Molding RFID tags and electronic antennas into plastic parts presents growing opportunities--and challenges. LIM & LSR Molding. Injection Molding. Matthew Naitove. Contributing Editor, Plastics Technology.

injection molding solutions examples

Did you know that Radio Frequency Identification (RFID) can be a powerful tool for protecting and tracking valuable injection molded parts and components? RFID systems use radio waves to transfer data, making them highly effective in a variety of environments. Durable RFID Tags for Harsh Conditions.The manufacturing RFID system embeds RFID tags into injection molds, allowing each mold to carry unique identification information. RFID readers collect this data and interface with software that manages mold location, status, and usage history.

Würth Elektronik, a German company that manufactures printed circuit boards, has developed a tag that can withstand the injection-molding process, so it can be embedded in crates (see Würth Elektronik Manufactures a Tougher Breed of Tag).

This white paper aims at using the example of manufacturing plastics with injection molding machines to describe how Industry 4.0 can quite easily gain entry into production, make processes more efficient and minimize costs.Embeddable RFID Tags for Manufacturing are designed to be injection-molded by OEMs and suppliers into their consumables, parts, and systems. By adding RFID capabilities at point-of-manufacture , they enable the digitization of integrated supply chains with real-time information and added flexibility.

Identify, protect and track valuable assets with embedded RFID. Texas Injection Molding collaborates with leading RFID hardware and Systems Integrators to bring the experience of plastic injection molding to embedded RFID. Balluff offers a simple plug-and-play solution to record and manage injection mold data. Using RFID, our new digital tool management system, Connected Mold-ID, provides tool data including details of the tool’s history, production cycles, and current status of the individual Mold-ID systems.Connected Mold-ID is the simple entry into digital tool management. With this plug-and-play solution you can collect and manage your injection molds automatically. Connected Mold-ID enables optimal utilization of your molds while preventing mold failures and reducing unplanned downtimes. The autonomous RFID system reliably

does a cellular can read nfc

The automatic documentation of mold usage via RFID enables optimal utilization and high availability of your injection molds. A separate shot counter records all production cycles for this purpose and the system provides you with all data on a .

does iphone 12 pro have nfc reader

injection molding solutions

Hi, my digital keys have been working perfectly until last week when my car went back to BMW to have the new software update installed version 07/2022 now the ultra .

rfid system for injection molds|injection molding solutions