wet rfid tag inlays In the wide application of RFID technology, wet inlay and dry inlay are two common forms of tags, each with its advantages. This article will comprehensively compare the two inlays and explore the differences in their manufacturing . • A Comprehensive Technical Overview of Contactless• Contactless.info, archived from the original on 24 April 2014 is designed to provide information for UK retailers that have an interest in Contactless card acceptance] See more

0 · wet vs rfid inlays

1 · wet vs dry rfid adhesive

2 · rfid tags

3 · rfid labels

4 · avery dennison rfid inlay

5 · avery dennison rfid

Wet RFID inlays may be more suitable for applications where exposure to moisture or humidity is a concern due to their immediate adhesion properties. Dry RFID inlays might be preferred for applications where precise .RFID Wet Inlays are best for applications where a low-cost “peel-and-stick” tag is needed. Any RFID Wet Inlay can also be converted into a paper or synthetic face label. Atlas offers almost .In the wide application of RFID technology, wet inlay and dry inlay are two common forms of tags, each with its advantages. This article will comprehensively compare the two inlays and explore the differences in their manufacturing . Wet RFID inlays may be more suitable for applications where exposure to moisture or humidity is a concern due to their immediate adhesion properties. Dry RFID inlays might be preferred for applications where precise placement or embedding within specific materials is necessary.

RFID Wet Inlays are best for applications where a low-cost “peel-and-stick” tag is needed. Any RFID Wet Inlay can also be converted into a paper or synthetic face label. Atlas offers almost every RFID Wet Inlay on the market, including the Smartrac Dogbone and Alien Squiggle.

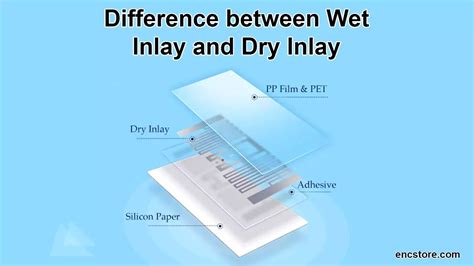

In the wide application of RFID technology, wet inlay and dry inlay are two common forms of tags, each with its advantages. This article will comprehensively compare the two inlays and explore the differences in their manufacturing materials, durability, cost, and applicable environment.RFID inlays and tags for all frequencies, applications, and preferences. Our extensive RFID technology portfolio covers a wide range of inlay designs for operation in the UHF, HF and NFC frequency bands, and are commonly found in a wide range of industries - including apparel, beauty and personal care, food, automotive, aviation .The inlay is size-optimized for 100 mm / 4 inch wide converted labels, and is available in dry, wet and paper tag delivery formats. The inlays and tags are compliant with ISO 9001:2015 Quality Management and ISO 14001:2015 Environmental Management, which ensure a reliable and state-of-the-art product that meets a variety of application needs . Wet Inlays – a Pressure Sensitive Inlays – same as Dry Inlay above, with the addition of a “wet” adhesive backing and liner. Encapsulated or Durable Finished Transponders – an inlay with the addition of a durable encapsulate for longer tag life.

Wet inlay, due to its convenient usage and excellent performance, has become a preferred RFID solution for many enterprises. This article uses the Alien Higgs®EC UHF RFID Wet Inlay as an example to help users better understand how to use RFID wet inlay and some key considerations.The Avery Dennison Smartrac DogBone RFID Wet Inlays excel with superior performance inside of demanding environments and on tough-to-tag materials, due to the inlay's exceptional tolerance against the detuning effect of high dielectric materials.` Wet versus dry — Adhesive-backed inlays are most common and can be used when no ancillary operations are required. These “wet” inlays typically come in rolls and can be quickly peeled off and adhered to the product. A wet inlay is delivered to the converter attached to a .Wet inlay RFID tags are a type of RFID (Radio Frequency Identification) tag consisting of an integrated circuit (IC) chip attached to an antenna, which is then sandwiched between two layers of material, usually paper or plastic.

what types of rfid tags are there

Wet RFID inlays may be more suitable for applications where exposure to moisture or humidity is a concern due to their immediate adhesion properties. Dry RFID inlays might be preferred for applications where precise placement or embedding within specific materials is necessary.RFID Wet Inlays are best for applications where a low-cost “peel-and-stick” tag is needed. Any RFID Wet Inlay can also be converted into a paper or synthetic face label. Atlas offers almost every RFID Wet Inlay on the market, including the Smartrac Dogbone and Alien Squiggle.In the wide application of RFID technology, wet inlay and dry inlay are two common forms of tags, each with its advantages. This article will comprehensively compare the two inlays and explore the differences in their manufacturing materials, durability, cost, and applicable environment.

RFID inlays and tags for all frequencies, applications, and preferences. Our extensive RFID technology portfolio covers a wide range of inlay designs for operation in the UHF, HF and NFC frequency bands, and are commonly found in a wide range of industries - including apparel, beauty and personal care, food, automotive, aviation .The inlay is size-optimized for 100 mm / 4 inch wide converted labels, and is available in dry, wet and paper tag delivery formats. The inlays and tags are compliant with ISO 9001:2015 Quality Management and ISO 14001:2015 Environmental Management, which ensure a reliable and state-of-the-art product that meets a variety of application needs . Wet Inlays – a Pressure Sensitive Inlays – same as Dry Inlay above, with the addition of a “wet” adhesive backing and liner. Encapsulated or Durable Finished Transponders – an inlay with the addition of a durable encapsulate for longer tag life.

Wet inlay, due to its convenient usage and excellent performance, has become a preferred RFID solution for many enterprises. This article uses the Alien Higgs®EC UHF RFID Wet Inlay as an example to help users better understand how to use RFID wet inlay and some key considerations.

The Avery Dennison Smartrac DogBone RFID Wet Inlays excel with superior performance inside of demanding environments and on tough-to-tag materials, due to the inlay's exceptional tolerance against the detuning effect of high dielectric materials.` Wet versus dry — Adhesive-backed inlays are most common and can be used when no ancillary operations are required. These “wet” inlays typically come in rolls and can be quickly peeled off and adhered to the product. A wet inlay is delivered to the converter attached to a .

wet vs rfid inlays

wet vs dry rfid adhesive

when were rfid tags implemented in texas

green-bay-packers Packers. Bears add Yannick Ngakoue to bolster league .

wet rfid tag inlays|wet vs dry rfid adhesive